Leave Your Message

-

Phone

-

E-mail

In the rapidly evolving landscape of sustainable manufacturing, the role of Forged Steel Parts has become increasingly critical. According to a report by the World Steel Association, the steel industry is responsible for approximately 7% of global CO2 emissions, prompting a significant shift towards more sustainable production methods. As manufacturers seek alternatives that align with environmental goals, the demand for Forged Steel Parts—known for their durability and strength—continues to rise.

Additionally, a market analysis by Grand View Research projects that the global forged steel market will reach $97.67 billion by 2025, driven by innovations in eco-friendly manufacturing techniques. This paradigm shift not only reflects growing consumer expectations for sustainability but also emphasizes the need for advanced technologies that reduce waste and enhance efficiency in producing Forged Steel Parts.

The manufacturing industry is undergoing a significant transformation as sustainability becomes a paramount concern. In the production of forged steel parts, innovative techniques are emerging to minimize environmental impact while ensuring robust performance. Techniques such as electric arc furnaces (EAF) are gaining traction, as EAFs use 70% less energy compared to traditional blast furnaces and reduce greenhouse gas emissions significantly by recycling scrap steel. According to a report by the World Steel Association, the steel industry is responsible for approximately 7% of global CO2 emissions, making these advancements critical for future growth.

Tips for manufacturers looking to adopt these sustainable practices include embracing automation and digital technologies. Implementing smart manufacturing systems can optimize energy use and reduce waste throughout the production process. Additionally, investing in advanced forging technologies, such as hot die forging, can improve material efficiency and enhance the mechanical properties of forged products while using fewer resources.

The industry's push for sustainability is not just a trend but a necessity for long-term viability. By focusing on innovative production methods that prioritize environmental stewardship, manufacturers can meet both market demands and regulatory pressures. As a result, the future of forged steel parts will undoubtedly be shaped by these evolving practices, aligning economic growth with ecological responsibility.

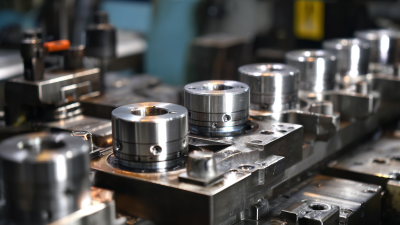

The integration of recycled materials in forged steel manufacturing is poised to revolutionize the industry, aligning it with the growing demand for sustainability. By utilizing scrap steel and other recycled metal sources, manufacturers not only reduce the reliance on virgin materials but also decrease the carbon footprint associated with production processes. The forging process itself can be optimized to handle these recycled materials efficiently, ensuring that the final products maintain the same high quality and performance standards expected in various applications, from automotive components to industrial machinery.

Moreover, this shift towards incorporating recycled materials signals a broader commitment to sustainable practices within the manufacturing landscape. As companies seek ways to minimize waste and maximize resource efficiency, the focus on recycling opens new avenues for innovation. Advanced sorting and processing technologies have emerged, allowing for a more effective integration of recycled content into forged steel. This not only enhances the environmental sustainability of the production cycle but also creates economic advantages for businesses by reducing material costs and promoting a circular economy where materials are reused rather than discarded.

| Material Type | Percentage of Recycled Content (%) | Energy Savings per Ton (kWh) | CO₂ Emissions Reduction (kg) | Applications |

|---|---|---|---|---|

| Low-alloy Steel | 60 | 200 | 300 | Automotive Components |

| Stainless Steel | 50 | 250 | 400 | Construction and Infrastructure |

| Carbon Steel | 70 | 180 | 350 | Heavy Machinery Parts |

| Tool Steel | 40 | 300 | 500 | Precision Tools |

The future of forged steel parts hinges significantly on the integration of digital technology, which plays a crucial role in promoting sustainability within the manufacturing sector. By employing advanced data analytics and machine learning, manufacturers can optimize their production processes, reducing waste and energy consumption. Real-time monitoring systems allow for better resource management, enabling companies to identify inefficiencies in their workflows and adjust operations accordingly. This shift not only minimizes environmental impact but also improves the overall cost-effectiveness of manufacturing forged steel components.

Furthermore, digital technologies such as the Internet of Things (IoT) and blockchain are revolutionizing the supply chain transparency of forged steel parts. IoT devices provide continual data on material usage and performance, fostering improved tracking of resources from procurement to production. Meanwhile, blockchain technology enhances traceability and accountability, ensuring that sustainable practices are followed throughout the supply chain. As these technologies become more integrated, forged steel manufacturers will be better positioned to meet the growing demand for environmentally friendly practices while maintaining high standards of quality and efficiency.

As the world pivots towards sustainability, regulatory trends are playing a critical role in shaping the future of steel forging practices. Governments worldwide are increasingly focusing on environmental impact assessments and emissions regulations, compelling manufacturers to adopt greener processes. Compliance with these evolving standards not only mitigates environmental footprints but also enhances the competitive edge of companies committed to sustainable practices.

Moreover, innovations in materials and techniques are complementing regulatory demands. The rise of carbon-neutral steel production and efficient resource use are becoming focal points. New regulations are incentivizing the adoption of technologies that minimize waste, optimize energy consumption, and lower greenhouse gas emissions. This shift towards sustainability is creating a dynamic landscape in which forged steel manufacturers must adapt to maintain market viability while contributing positively to their communities and the environment.

In the evolving landscape of sustainable manufacturing, industry partnerships play a crucial role in the advancement of steel forging technologies. As outlined in recent reports, the global steel industry is responsible for approximately 7-9% of total greenhouse gas emissions. To combat this, collaborations like that between UNSW Sydney and India's Steel Research & Technology Mission are pivotal. By sharing knowledge and resources, these organizations aim to innovate sustainable practices and enhance the efficiency of steel production, ultimately contributing to a significant reduction in carbon emissions.

Furthermore, the innovative application of cutting-edge technologies, such as blockchain and artificial intelligence, is revolutionizing the circular economy within the metal industry. Reports indicate that the adoption of these technologies can streamline operations and optimize recycling processes, thereby reducing waste and supporting a more sustainable lifecycle for forged steel products. Companies leveraging these advancements, such as those practicing green steelmaking, demonstrate a commitment to minimizing their environmental footprint, highlighting the industry's potential to lead in sustainable progress through collaboration and technology-driven solutions.