Leave Your Message

-

Phone

-

E-mail

Forged Cylinders play a crucial role in various industrial applications. Renowned expert Dr. Emily Carter states, "Forged Cylinders are the backbone of many industrial processes." This highlights their significance in enhancing both efficiency and durability.

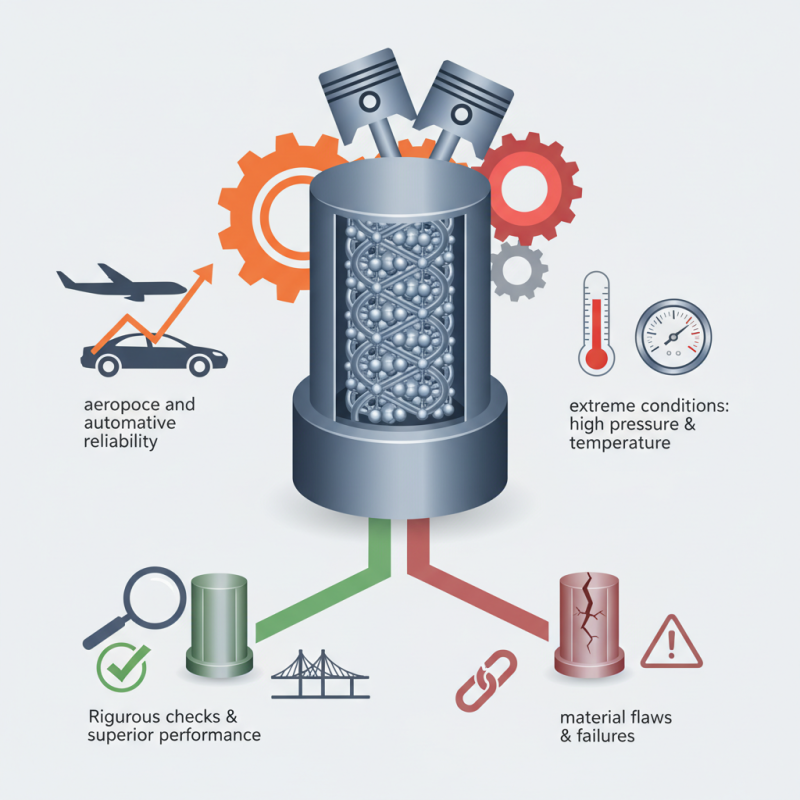

In industries such as aerospace and automotive, Forged Cylinders help ensure reliability under extreme conditions. These components withstand high pressures and temperatures. The forging process creates a strong molecular structure, leading to superior performance. However, the challenge lies in ensuring that every cylinder meets stringent quality standards.

Despite advancements, some manufacturers struggle with consistency. Flaws in material or processing can lead to failures. This oversight can have serious repercussions in critical applications. Thus, the importance of rigorous checks cannot be overstated. In the end, while the benefits of Forged Cylinders are clear, the industry must reflect on its standards and practices.

Forged cylinders play a crucial role in many industrial sectors. Their strength and durability are unmatched. According to a recent report by the International Journal of Material Science, forged components can withstand stress up to 25% more than their cast counterparts. This advantage is vital in high-pressure environments. For industries like aerospace and automotive, the reliability of every component is essential.

Forged cylinders are essential in maintaining operational efficiency. In manufacturing, machinery often operates in harsh conditions. The performance of these machines depends on the quality of components. A slight failure due to inferior materials can lead to significant downtime. Studies show that replacing defective parts can cost companies an average of $22,000 per hour. Thus, using forged cylinders reduces repair frequency and increases productivity.

Moreover, forged cylinders offer a level of design flexibility. They can be produced to specific dimensions while maintaining integrity. This adaptability is crucial in custom applications. However, the production process is not without challenges. Forging requires precise control of temperature and pressure. Any deviation can impact the final product's quality. Each step must be meticulously planned to avoid costly errors.

| Application Area | Forged Cylinder Material | Advantages | Common Industries |

|---|---|---|---|

| Hydraulic Systems | Carbon Steel | High strength, durability | Construction, Oil & Gas |

| Pneumatic Equipment | Aluminum Alloy | Lightweight, corrosion resistant | Manufacturing, Automotive |

| Engine Components | Stainless Steel | High-temperature resistance | Aerospace, Marine |

| Industrial Machinery | Alloy Steel | Enhanced toughness and fatigue resistance | Mining, Heavy Equipment |

| Pressure Vessels | Titanium | Excellent strength-to-weight ratio | Chemical Processing, Energy |

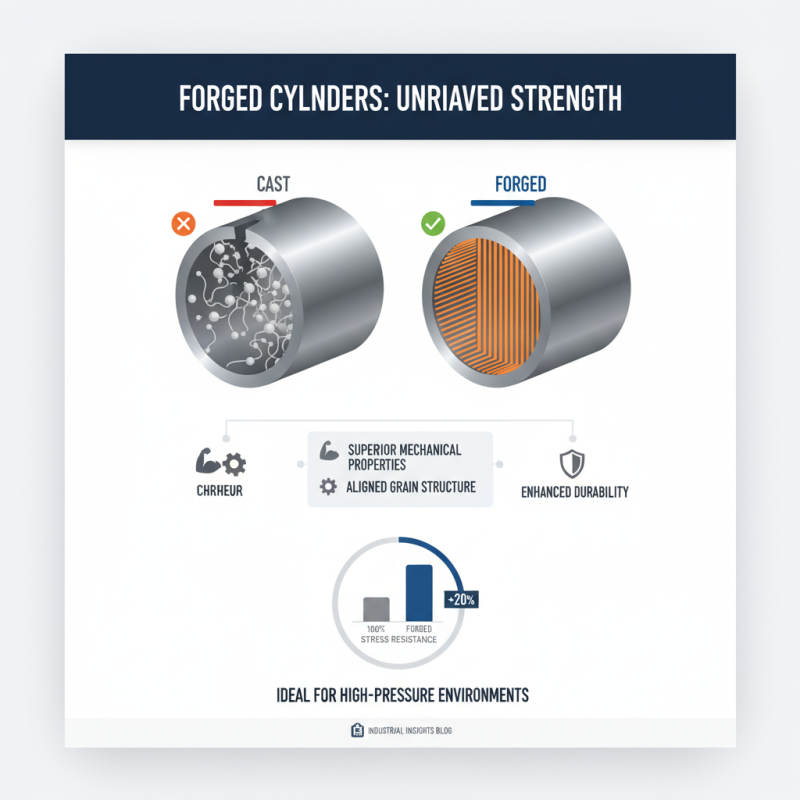

Forged cylinders play a vital role in various industrial applications. Their strength and durability significantly enhance performance. Data from the International Journal of Advanced Manufacturing Technology indicates that forged components exhibit a 20-30% improvement in strength compared to cast counterparts. This strength is essential in high-pressure and high-temperature environments.

One notable advantage of forged cylinders is their resistance to fatigue. The continuous grain structure in forged materials reduces the likelihood of cracks. For instance, studies show that forged cylinders can endure up to 50% more cycles in fatigue tests than cast ones. This is crucial for industries like aerospace and automotive, where reliability is non-negotiable.

Tip: Regularly inspect your forged components for signs of wear. This will help maintain optimal performance over time. It’s worth noting that while forged cylinders offer numerous benefits, they can be more expensive than cast options. Evaluate your application needs carefully. Remember, the longevity of forged cylinders can offset the initial costs.

Another benefit is their ability to withstand extreme conditions, including corrosive environments. Data from the Materials and Design journal confirms that forged materials have enhanced corrosion resistance. This quality is vital in industries such as oil and gas. However, some may overlook proper maintenance, leading to unforeseen failures.

Forged cylinders play a crucial role in many industrial applications. They provide reliability and strength, essential for machinery and equipment. These components are often found in the automotive sector, where they endure high stress. The forging process enhances their durability, making them suitable for high-performance engines.

In the aerospace industry, forged cylinders are vital for aircraft components. They must withstand extreme conditions while maintaining precision. These parts help ensure safety and efficiency during flight. Forged cylinders are also significant in the manufacturing sector. They are used in hydraulic systems, where precision and power are necessary.

Despite their importance, not all industries fully utilize forged cylinders. Some businesses may overlook the benefits due to cost concerns. There is also a lack of awareness about the advantages they offer. Understanding their value could lead to better performance and reliability. Forged cylinders can enhance safety and reduce maintenance needs. The decision to invest in quality materials is a significant step, but it often requires careful consideration.

The manufacturing process of forged cylinders begins with selecting high-quality metal alloys. These materials are chosen for their strength and durability. The raw metal is heated to a specific temperature. Once heated, it becomes malleable and can be shaped more easily.

Next, the heated metal is placed into a forge. This machine uses intense pressure to shape the metal into a cylinder. The forging process can lead to some imperfections. These imperfections may require additional refining. However, they can also contribute to unique properties in the finished product. After forging, the cylinders undergo machining to achieve precise dimensions. This step is crucial, as tight tolerances are often needed for industrial applications.

Finally, quality control is essential. Each cylinder must meet specific standards to ensure reliability. These checks may reveal some inconsistencies. Sometimes, these issues stem from the forging process itself. Each stage in the manufacturing journey of forged cylinders is critical. Small errors can have significant effects on performance.

Forged cylinders are critical in industrial applications due to their superior mechanical properties. Unlike cast cylinders, forged versions undergo a process that aligns the internal grain structure. This results in enhanced strength and durability. Reports indicate that forged cylinders can withstand stresses up to 20% higher than their cast counterparts. The toughness they provide is essential in high-pressure environments.

When comparing forged and cast cylinders, the choice often boils down to intended use. Cast cylinders are often cheaper to produce. However, they may develop cracks or weaknesses over time. Forged cylinders are costlier but offer much greater reliability. Industries such as aerospace and automotive recognize the importance of this reliability. A study found that using forged components can reduce the failure rates by approximately 30%.

Tip: Always conduct a risk assessment before choosing between forged and cast components. Analyze the specific needs of your application. It may save costs in the long run.

In certain environments, the heightened performance of forged cylinders may not justify the extra cost. Assessing your operational demands is crucial. Some manufacturers prefer cast cylinders for low-stress applications. Understanding your industry specifics will lead to more informed decisions.