Leave Your Message

-

Phone

-

E-mail

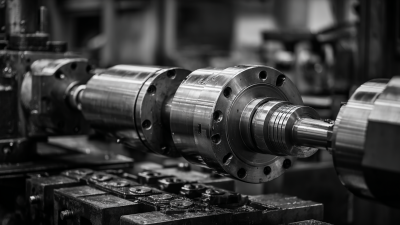

In the world of manufacturing, Hot Forging Parts play a crucial role. These parts undergo a transformative process that shapes materials under high temperature and pressure. According to industry expert John Mitchell, “Hot forging enhances strength and durability, making parts more reliable.”

The significance of Hot Forging Parts cannot be understated. They are essential in various sectors, including automotive and aerospace. This process often results in less waste, making it a cost-effective choice. However, achieving optimal results requires precise control. Inexperience can lead to defects or material failure, which is a major concern.

Despite its advantages, the hot forging process has its challenges. For instance, not every material responds well to this method. Understanding the limitations is crucial. As we explore the intricacies of Hot Forging Parts, one must reflect on both the potential and the pitfalls. What lessons have we learned? How can we improve?

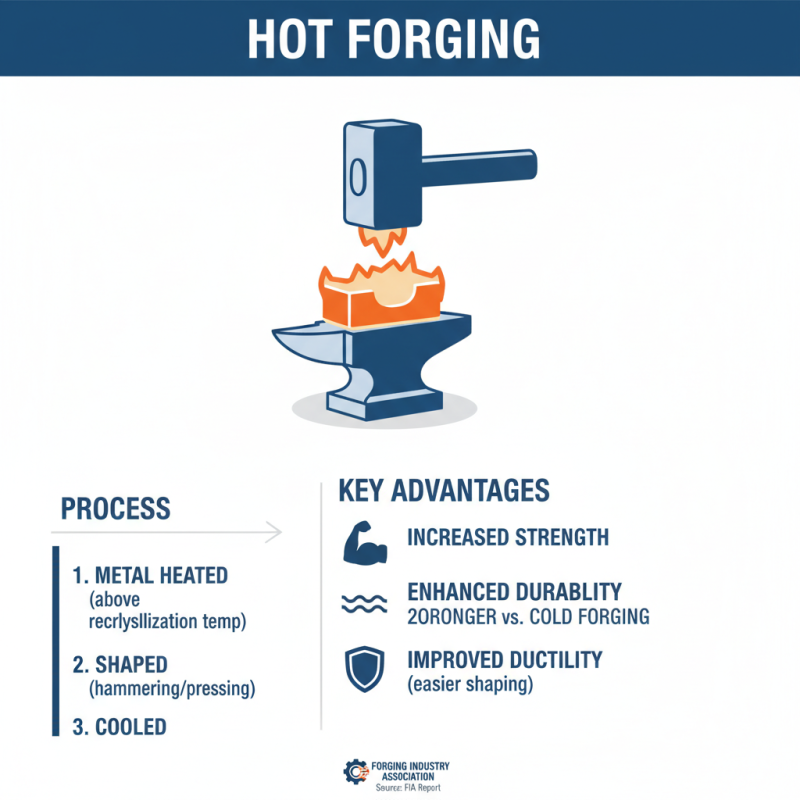

Hot forging is a vital process in manufacturing. It involves shaping metal using high heat, typically above the recrystallization temperature. This method enhances the material’s mechanical properties. According to a recent industry report, hot forged parts often exhibit 20-30% higher strength compared to their cold-forged counterparts. This strength is appealing in various applications, including automotive and aerospace sectors.

The importance of hot forging extends beyond strength. It allows for complex shapes with excellent precision. Data indicates that 85% of the forged parts produced today utilize hot forging techniques. This process can reduce machining time, which lowers production costs.

However, not all materials respond well to hot forging. Some alloys may degrade under intense heat. Manufacturers must choose materials carefully to avoid failures.

Environmental considerations also come into play. The high energy consumption during hot forging poses challenges. Companies are exploring greener methods to reduce their carbon footprint. There are ongoing debates within the industry about the balance between efficiency and sustainability. Each choice impacts overall effectiveness and environmental impact. This tension highlights the need for continual improvement and innovation in hot forging practices.

Hot forging is a manufacturing process that can significantly improve the strength of metals. Various materials are suitable for hot forging, each with unique properties. Steel is commonly used due to its high durability and strength. Aluminum, though lighter, offers excellent corrosion resistance. Manufacturers also use titanium because of its high strength-to-weight ratio.

When considering materials for hot forging, one must reflect on the specific applications. Some metals may not achieve the desired properties after forging. It’s vital to choose the right type of alloy. Each alloy behaves differently under heat and pressure. A material that works well for one application may fail in another. Don’t overlook the properties required for your specific use.

Tips: Always perform tests before large-scale production. This ensures that the forged parts meet the necessary standards. Also, watch out for temperature control during the process. Too high a temperature can harm certain materials. Understand the limits and capabilities of your chosen materials. Make adjustments as needed.

Hot forged parts are integral across various industries. They exhibit superior strength and durability, making them vital for applications in automotive, aerospace, and construction. The automotive sector relies heavily on hot forgings for engine components, gears, and chassis parts. These components endure high stress, and forged materials provide the necessary resilience.

In aerospace, the need for lightweight yet strong materials is critical. Hot forged parts fit the bill perfectly, offering reliable performance in aircraft structures and engine components. Furthermore, sectors like construction utilize these parts for heavy machinery and tools. The strength of hot forged steel means safety and longevity for equipment on job sites.

However, challenges exist in this process. The energy consumption in forging can be significant. Also, ensuring quality control during mass production is demanding. Occasionally, defects can arise, leading to costly rework. These issues highlight the complexity of utilizing hot forged parts effectively across various applications. Continuous improvement efforts must focus on efficiency and precision to enhance the benefits of hot forging in industry.

Hot forging is a significant manufacturing technique in the metalworking industry. It involves shaping metal at elevated temperatures, enhancing its ductility. A report by the Forging Industry Association indicates that hot forging can improve mechanical properties by over 20% compared to cold forging. This results in stronger and more durable products.

One major benefit of hot forging is its ability to produce complex shapes with minimal waste. This technique can efficiently create parts like gears and valves that require high precision. Studies show that hot forging can reduce material waste by up to 15%. However, the initial setup costs can be high. This raises concerns for smaller manufacturers with limited budgets.

The thermal treatment during hot forging also refines the microstructure of metals. This results in a more uniform grain structure, which can lead to improved performance in demanding applications. Despite its advantages, challenges in controlling temperature and time are apparent. Precision is crucial, and mistakes can lead to defects, necessitating continuous monitoring.

When it comes to hot forging parts, various factors determine their quality. One significant aspect is the temperature during the forging process. If the temperature is too high or too low, it can lead to defects. This can include cracks or weak spots in the metal. Choosing the right temperature is essential.

Another factor is the material used for forging. Different metals respond uniquely to heat and pressure. Some metals may become brittle when subjected to high temperatures. Testing the material properties beforehand can save time and resources. Always consider how the material behaves during the forging process.

The design of the part also plays a crucial role in its performance. Complex shapes may be difficult to forge correctly. This can lead to inconsistencies in strength and finish. Simplifying designs could improve overall quality and ease production. Reflecting on these factors is vital for achieving the best results in hot forging.

| Parameter | Influence on Quality | Best Practices |

|---|---|---|

| Material Type | Affects durability and strength | Use high-grade materials |

| Temperature Control | Improves material flow and properties | Maintain optimal forging temperature |

| Forging Speed | Impacts surface finish and microstructure | Adjust speed to suit material |

| Die Design | Affects dimensional accuracy | Invest in precision die designs |

| Cooling Rate | Influences final properties | Control cooling to minimize defects |

| Quality Control | Ensures consistency and reliability | Implement thorough inspections |