Leave Your Message

-

Phone

-

E-mail

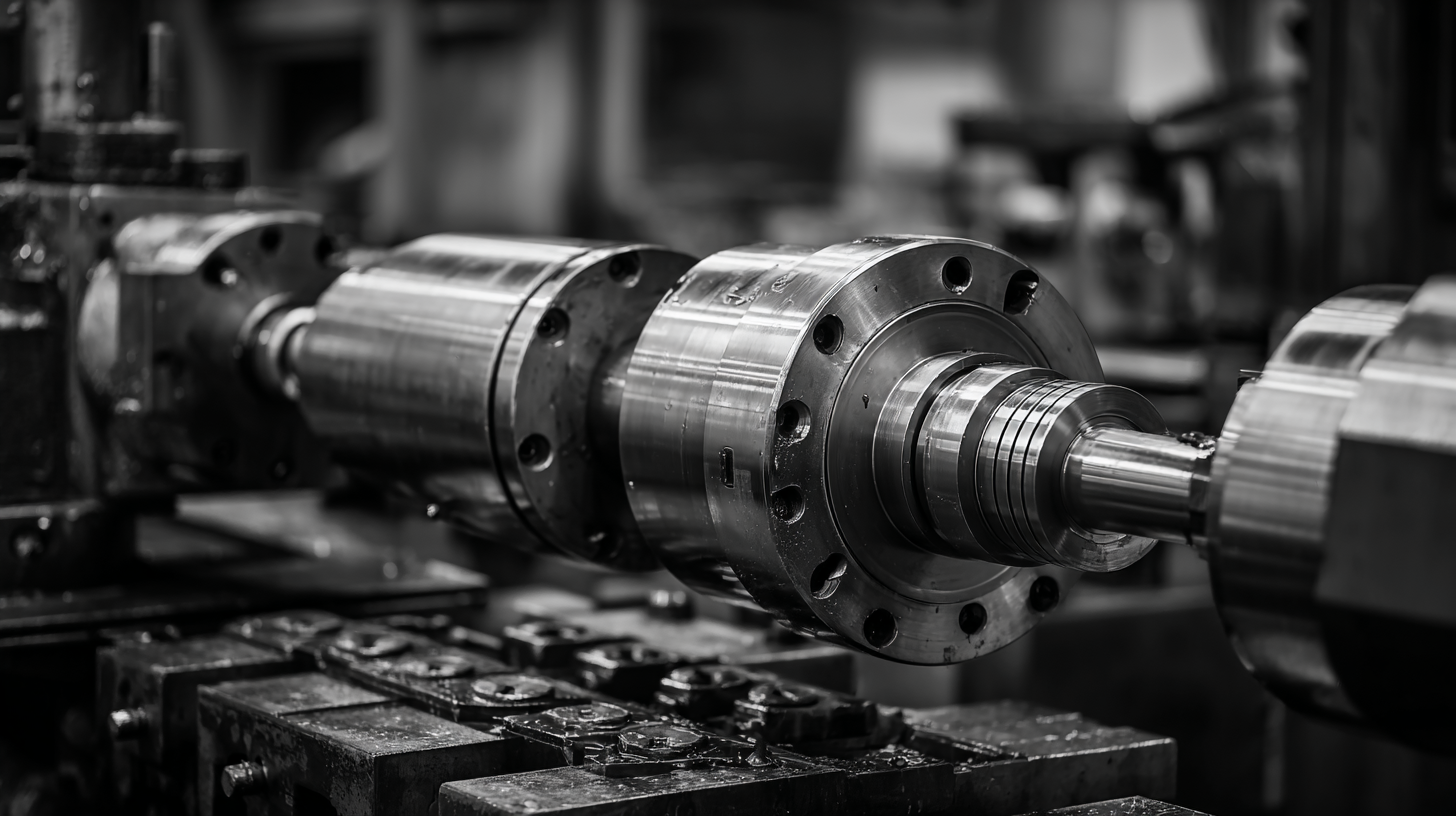

In the world of manufacturing, the efficiency and quality of production heavily rely on the components utilized in forging processes. Understanding the nuances of forging machine parts is crucial for any business looking to enhance their operations and ensure superior output. The right selection of these parts can lead to improved performance, increased longevity, and ultimately, better return on investment. However, with the myriad of options available, choosing the best forging machine parts can be a daunting task. This blog aims to unlock the secrets of optimal technical specifications and outlines key considerations and alternatives to help you navigate this complex landscape effectively. Whether you are a seasoned professional or new to the industry, this guide will equip you with the knowledge needed to make informed decisions that align with your production goals.

When it comes to selecting the right forging machine parts, understanding key technical specifications is crucial. Each component, whether it’s a die, hammer, or anvil, comes with unique parameters that dictate its performance and compatibility with your machinery. For instance, pay close attention to material composition, hardness levels, and dimensional tolerances, as these factors will significantly influence the durability and effectiveness of the part in action.

When it comes to selecting the right forging machine parts, understanding key technical specifications is crucial. Each component, whether it’s a die, hammer, or anvil, comes with unique parameters that dictate its performance and compatibility with your machinery. For instance, pay close attention to material composition, hardness levels, and dimensional tolerances, as these factors will significantly influence the durability and effectiveness of the part in action.

Tip: Always review the manufacturer's documentation thoroughly to ensure that the specifications align with your operational requirements. Look out for certifications or quality standards that can guarantee the reliability of the parts.

Another important aspect to consider is the manufacturer's reputation and support services. A well-established provider will not only offer better quality parts but also provide valuable after-sales service, which might include installation guidance, maintenance tips, and warranty information.

Tip: Don't hesitate to ask for references or case studies involving the parts in question. This will give you insights into their real-world performance and help you make an informed decision.

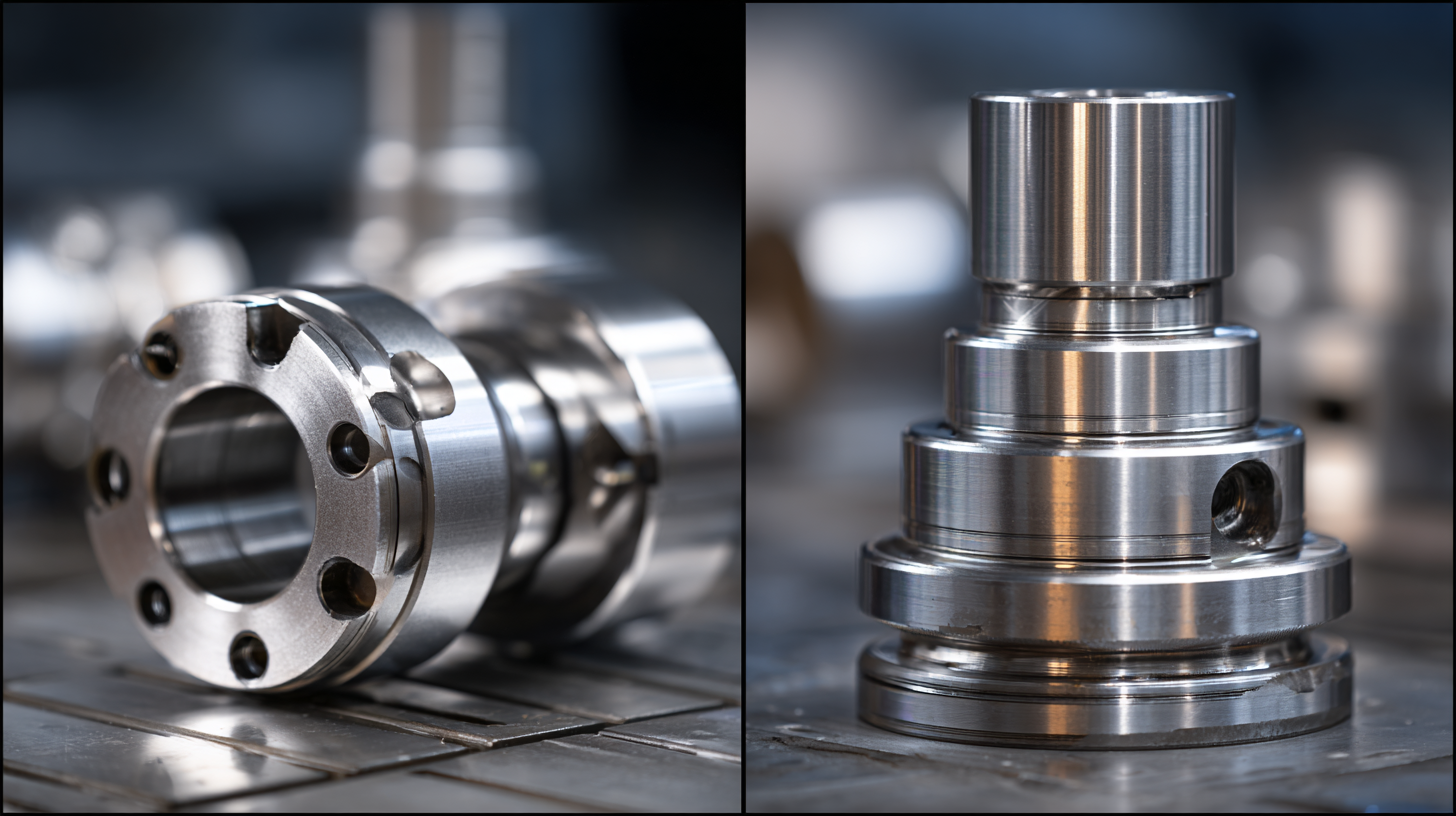

When selecting forging machine parts, evaluating the material composition is paramount to ensuring durability and optimal performance. The materials used in the construction of these parts significantly influence their resistance to wear and tear, as well as their ability to withstand extreme conditions. For instance, high-carbon steels often provide superior hardness and strength, making them ideal for high-load applications. In contrast, alloy steels infused with elements such as chromium and molybdenum can enhance toughness and reduce the risk of failure under stress. Understanding these material properties allows manufacturers to tailor their choices to specific operational demands.

Durability is another critical aspect that ties closely with material composition. Forging machine parts should be able to maintain their integrity over extended periods, even while subjected to intense pressure and temperature fluctuations. To achieve this, one must consider not just the primary material but also the heat treatments and surface finishes applied. Techniques like nitriding or tempering can significantly elevate a part's lifespan, further mitigating the risks associated with fatigue or corrosion. Therefore, a comprehensive evaluation of both material composition and the treatments employed is essential for selecting parts that will ensure high performance and longevity in any forging operation.

When it comes to selecting the right forging machine, understanding the differences between hydraulic and mechanical forging machines is crucial. Hydraulic presses utilize fluid power to generate force, allowing for greater flexibility in the deformation of materials. This type of machine is particularly effective for producing complex shapes and can handle a wide range of materials, making it ideal for applications in industries like aerospace where specific geometries are often required. The ability to easily adjust pressure also means that hydraulic machines can accommodate various thicknesses and densities, adding to their versatility.

On the other hand, mechanical forging machines operate through a system of gears and levers to deliver consistent force, which can result in faster production rates. They are especially well-suited for high-volume operations where efficiency is paramount. Additionally, mechanical presses often have lower operational costs over time, as they typically require less maintenance compared to their hydraulic counterparts. When choosing between hydraulic and mechanical forging machines, factors such as production volume, material properties, and specific part requirements should guide the decision, ensuring optimal performance tailored to manufacturing needs.

| Specification | Hydraulic Forging Machines | Mechanical Forging Machines |

|---|---|---|

| Force Output | High (10,000 - 50,000 lbs) | Moderate (5,000 - 20,000 lbs) |

| Speed | Moderate (10 - 30 strokes/min) | High (50 - 200 strokes/min) |

| Energy Efficiency | Higher | Lower |

| Maintenance Cost | Moderate | Lower |

| Flexibility | Very Flexible | Less Flexible |

| Typical Applications | Precision Forging | Heavy-Duty Forging |

| Initial Investment | Higher | Lower |

When selecting forging machine parts, one must consider a variety of essential factors to ensure the best fit for specific applications. First and foremost, it is crucial to analyze the material specifications of the parts. The materials should not only be compatible with the forging process but also possess the necessary properties to endure the extreme conditions often involved in forging operations. Factors such as tensile strength, hardness, and resistance to wear and corrosion play a vital role in determining the longevity and efficiency of the machine parts.

Another key consideration is the precision and tolerances of the parts. High precision is required for optimal performance, as even minor discrepancies can lead to significant inefficiencies or failures during operation. It is also important to verify the manufacturer’s reputation and adherence to quality standards, as reliable sources are crucial for ensuring the durability and safety of forging machine parts. Additionally, understanding the specific requirements of the forging process—such as temperature ranges and type of materials being forged—will aid in identifying the most suitable components. By carefully evaluating these factors, operators can select forging machine parts that enhance productivity and reduce downtime in their manufacturing processes.

Precision engineering plays a crucial role in enhancing the efficiency and quality of forging processes. By ensuring that every component fits perfectly and operates seamlessly, precision engineering minimizes material waste and reduces machine downtime. High-quality forging machine parts, crafted with meticulous attention to detail, can significantly improve the overall performance of forging operations. This not only leads to better productivity but also enhances the durability of the components produced.

When selecting forging machine parts, one essential tip is to prioritize materials that provide superior strength and wear resistance. Opt for parts manufactured using advanced techniques such as CNC machining or additive manufacturing, as these methods often achieve tighter tolerances and better finish quality. Additionally, consult with suppliers about their quality control measures; reputable manufacturers will employ rigorous testing protocols to ensure their parts meet industry standards.

Another vital tip is to consider the customization options available. Off-the-shelf components may not always meet the specific requirements of your projects. Collaborating with manufacturers who offer tailored solutions can lead to significant improvements in performance and efficiency. Understanding your operational needs and specifying them clearly can help you select parts that align perfectly with your forging machine’s capabilities.