Leave Your Message

-

Phone

-

E-mail

In the industrial landscape of 2026, forged steel parts play a crucial role. The global market for forged steel is projected to reach $120 billion, indicating its significance. Industries such as automotive, construction, and oil and gas heavily rely on these components for their durability and strength.

Forged steel parts are favored for their superior mechanical properties. According to the Steel Association, forged parts exhibit improved fatigue resistance and toughness, essential for high-stress applications. Yet, not all forged steel parts meet stringent quality standards. Manufacturers face challenges in achieving optimal performance consistently. This inconsistency can lead to failures in critical situations, prompting a need for better quality control measures in production.

The future of forged steel parts hinges on innovation and sustainability. The push for eco-friendly manufacturing processes is growing. Companies are exploring recycled materials and advanced forging techniques. However, balancing cost and quality remains a significant hurdle. Industry professionals must critically assess the existing practices to enhance efficiency and minimize waste. As we delve into the best forged steel parts for industrial applications, these reflections are vital for shaping a more resilient future.

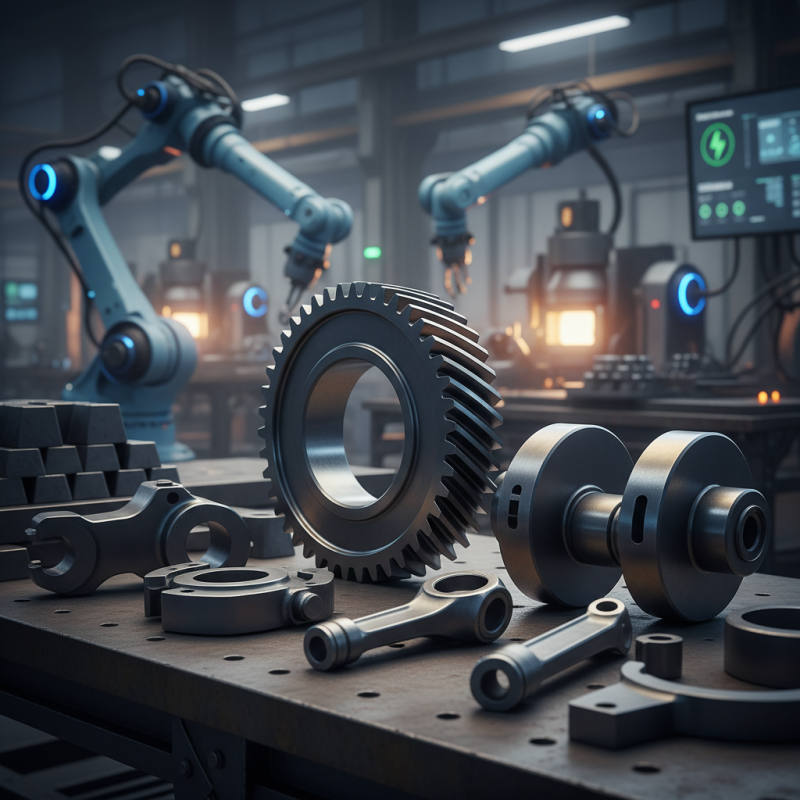

Forged steel parts play a crucial role in many industrial applications. Their strength and durability make them ideal for machinery, structural components, and tools. These parts undergo a process that refines their internal structure. This results in enhanced mechanical properties. However, not all forged steel parts are created equal. The quality depends greatly on the forging process and the material used.

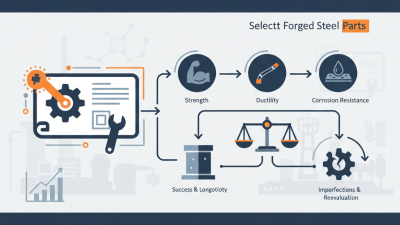

When selecting forged steel parts, consider the application requirements first. The intended use will dictate the necessary specifications. Different industries may require unique characteristics, like resistance to corrosion or extreme temperatures. This means you should not overlook the details. Inspecting the specific properties is essential for optimal performance.

Tips: Always test small batches before a larger order. This helps identify issues early on. If a part fails under stress, it can lead to costly downtime. Regularly evaluate suppliers to ensure quality control keeps improving. It's worth focusing on the long-term impact of material choice. Not every fabrication process is suited for all environments. Keep an open dialogue with your manufacturers to address potential flaws and refine your choices.

Forged steel is a key player in the industrial world. Its unique properties greatly enhance performance in various applications. The process of forging aligns the internal grain structure. This results in superior strength and toughness. Components made from forged steel can withstand higher levels of stress. They are less likely to fail under pressure.

One pivotal property of forged steel is its ductility. This allows for easy manipulation without cracking. Ductile materials can absorb impacts better, making them ideal for heavy machinery. Another important feature is its fatigue resistance. Forged steel exhibits excellent resistance to repeated stress cycles. This property is crucial for parts that experience constant movement.

However, not all forged steel parts are created equal. Some may not meet the rigorous standards of specific applications. Manufacturers must ensure quality control throughout the forging process. There can be hidden defects that reduce performance. Continuous improvement in techniques is essential for optimal results. Addressing these imperfections leads to better and more reliable products in the industrial sector.

Forged steel parts are vital in many industrial applications today. Industries like automotive, aerospace, and construction rely heavily on these components. They offer strength and durability, making them ideal for high-stress environments. Manufacturers prefer forged steel due to its ability to withstand extreme temperatures and pressures.

In the automotive industry, forged steel is commonly used in engine parts and transmission systems. These components need to endure constant stress and require high resilience. Similarly, the aerospace sector uses forged steel in landing gears and turbine blades. These applications demand exceptional reliability and performance.

Tips: Always consider the specific requirements of your project. Look for materials that meet industry standards. Not all forged steel is created equal, so research the properties you need.

The construction industry benefits from forged steel in structural components. Beams and columns often incorporate forged materials for added strength. However, not every application might need such robust parts. Sometimes, it is worth assessing whether a lighter material will suffice.

Tips: Evaluate the cost versus performance trade-offs before selecting your materials. Forged steel can be more expensive than alternatives, so choose wisely based on your project’s needs.

When selecting the best forged steel parts for industrial applications, several criteria stand out. Strength and toughness are critical. Industries rely on forged steel for its ability to withstand high stress. According to a report from the Steel Forging Association, forged steel parts can have tensile strengths exceeding 200 ksi, making them suitable for demanding applications.

Another essential factor is precision. Forged parts often come with tighter tolerances than cast alternatives. This precision reduces the risk of failure in high-stakes environments. A study published in the Journal of Materials Science highlights that 80% of failures in industrial components arise from inadequate material properties. Ensuring the right specifications is crucial.

Cost-effectiveness must also be considered. While forged steel can be more expensive initially, the long-term benefits often justify this investment. Components that last longer reduce replacement costs and downtime. Yet, it's important to reflect on the sourcing of materials and production methods. Not every supplier meets rigorous industry standards. Regular audits can help ensure quality over time.

The future of forged steel parts in industrial applications is fascinating yet challenging. Demand is expected to grow by 5% annually, according to the latest market reports. This growth is primarily driven by sectors like automotive and aerospace, where high strength and durability are crucial. The use of forged steel parts can significantly enhance the performance of critical components, leading to improved safety and efficiency.

However, the industry faces challenges. The rise of alternative materials presents competition. For instance, composite materials are lighter but may not match steel's strength. Companies need to balance cost and performance. Additionally, sustainability concerns are pressing. Manufacturing forged steel often involves high energy consumption. More efficient processes are essential. Companies are exploring advanced techniques, such as using electric furnaces.

Another emerging trend is digitalization. The integration of IoT in manufacturing processes is expected to improve quality control. This can lead to real-time monitoring and reduced waste. Yet, technological adoption has its hurdles. Small and medium-sized enterprises may struggle with costs. The shift requires investment in training and equipment, which can be daunting. The industry's future hinges on addressing these concerns while capitalizing on new opportunities.