Leave Your Message

-

Phone

-

E-mail

In 2026, the demand for Forged Cylinders continues to rise. These components play a crucial role in various industries. Understanding their features and applications is essential for manufacturers and engineers.

Forged Cylinders offer strength and durability. They are often used in high-pressure environments. However, choosing the right type can be challenging. Different materials and manufacturing processes affect performance. It’s important to analyze specific needs.

While Forged Cylinders have advantages, they can also present challenges. The cost and availability may vary significantly. Some may encounter quality control issues. It’s vital to consider these factors carefully. This article will explore key aspects of Forged Cylinders, helping you make informed decisions.

Forged cylinders play a crucial role in modern engineering. In 2026, their significance continues to rise. These components provide strength and durability in various applications. Industries rely on them for high-performance machinery. They are made by forging heated metal into shape, enhancing structural integrity. This process allows them to withstand extreme pressures and temperatures.

However, not all forged cylinders meet the necessary standards. Some may have internal flaws that can lead to failure during operation. Quality control is essential in manufacturing. Engineers need to select the right materials and processes to ensure reliability. A poor choice can result in costly downtime or accidents. The challenge is to balance performance and cost without compromising safety.

The demand for custom forged cylinders is growing. Each application has unique requirements. There’s a need for constant innovation in design and materials. Yet, as industries push for more robust solutions, some may overlook critical details. This oversight can have serious consequences. Continuous learning and improvement are essential to advancing forged cylinder technology.

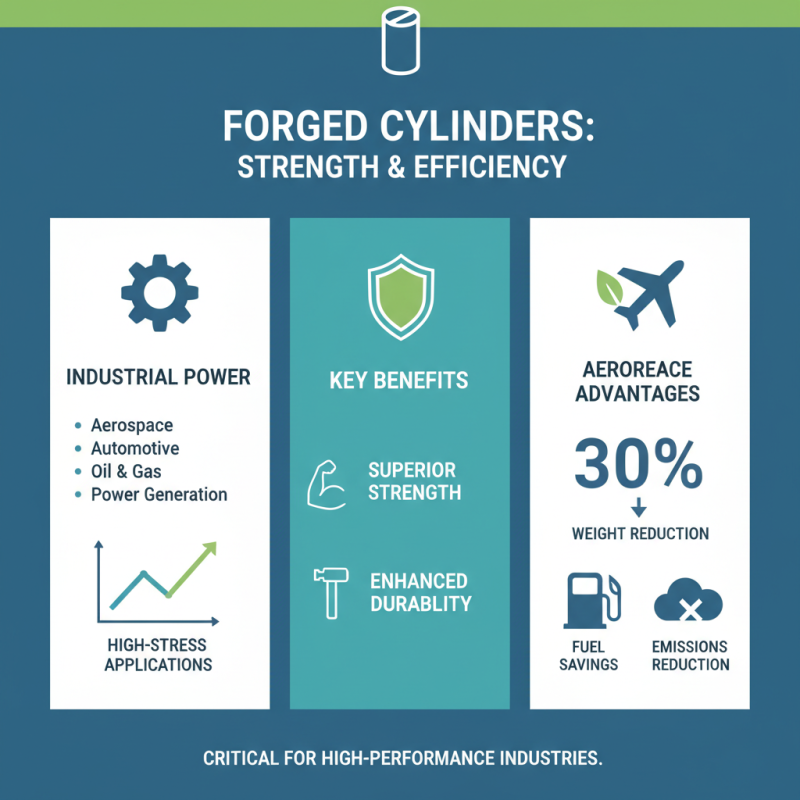

Forged cylinders are vital in various industries, from aerospace to automotive. The materials used in their manufacturing significantly influence performance and durability. Commonly, steel alloys dominate the market due to their strength and high-temperature resistance. Data from the Forging Industry Association indicates that carbon steel represents about 50% of forged cylinder materials used today.

Beyond steel, specialized alloys like titanium and aluminum are gaining traction. These materials are lighter and offer excellent corrosion resistance. A report by the American Institute of Steel Construction highlights that titanium can reduce overall vehicle weight by up to 30%, enhancing performance and fuel efficiency. However, these materials can be expensive and challenging to work with, making them less accessible for some manufacturers.

The selection of material is not always straightforward. Different applications require distinct characteristics. Forgers must balance cost, availability, and performance. There’s ongoing debate about which materials best meet evolving industry standards. These challenges reflect a sector that is constantly adapting, yet still grappling with material limitations and production constraints.

Forged cylinders are pivotal in various industries, from aerospace to automotive. Their strength and durability make them ideal for high-stress applications. In the aerospace sector, forged cylinders withstand extreme conditions. According to industry reports, these components can reduce weight by up to 30%. This efficiency is crucial for fuel savings and emissions reduction.

In oil and gas, the demand for forged cylinders increases. They are used in drilling equipment, pipelines, and valves. The American Petroleum Institute highlights that stronger materials improve safety and extend the life of critical components. However, choosing the right material remains a challenge. Companies often reflect on their material choices, questioning if they prioritize cost over quality.

Tips: When selecting forged cylinders, consider production methods. The type of forging can affect performance. Always weigh the benefits of durability against potential failures. Investing in quality ensures long-term success in demanding applications. Reflecting on these decisions can lead to better outcomes.

The forged cylinder production industry is evolving rapidly. Emerging technologies are reshaping how these components are manufactured. Automation and advanced materials are at the forefront of this change. For instance, a recent industry report indicates that automation can reduce production time by up to 40%. This efficiency is crucial as demand for high-quality forged cylinders increases.

Innovations in metallurgy are enabling better performance. New alloys are being developed that offer greater strength and durability. Reports show that using these advanced materials can enhance fatigue resistance by 30%. However, these innovations bring challenges. The production processes need to adapt and require skilled workers.

Industry leaders are investing in research and development. Yet, some companies struggle to keep pace with advancements. A lack of training and resources can lead to inefficiencies. As the market grows, addressing these gaps becomes essential. Ensuring that production methods are upgraded while maintaining quality is vital for future success.

When selecting forged cylinders, there are several critical factors to consider. Material composition plays a vital role. High-quality steel alloys are often preferred. They can withstand extreme conditions and provide durability. According to a recent industry report, nearly 70% of failures in forged components stem from improper material selection. This highlights the need to choose wisely.

In addition, the manufacturing process affects performance. Forging creates a denser grain structure in the metal. This can lead to improved strength and ductility. Studies show that forged cylinders offer 20-30% greater tensile strength compared to cast alternatives. However, not all manufacturers achieve the same quality. It’s essential to review production methods carefully.

Cost considerations cannot be overlooked. While forged cylinders may have a higher initial price, their longevity can lead to overall savings. The return on investment often justifies the expenditure. Still, it's crucial to evaluate whether the specific application warrants this investment. Balancing quality and cost is not always straightforward and requires reflection.

| Factor | Description | Importance Level | Recommended Material | Common Applications |

|---|---|---|---|---|

| Material Quality | The purity and composition of the material used in the forging process. | High | Alloy Steel | Automotive, Aerospace |

| Diameter & Length | The size specifications essential for fitting as per the design requirements. | Medium | Custom Forging | Machinery, Construction |

| Surface Finish | Quality of the surface finish to enhance durability and resistance. | High | Shot Peened | Oil & Gas, Heavy Industry |

| Heat Treatment | Heat treatments that enhance mechanical properties like strength and toughness. | High | Quenching & Tempering | Automotive, Aerospace |

| Cost Efficiency | Balance between cost and performance of the cylinder. | Medium | Carbon Steel | General Manufacturing |